Drawer Runner Rehabilitation: Smooth Sliding Solutions

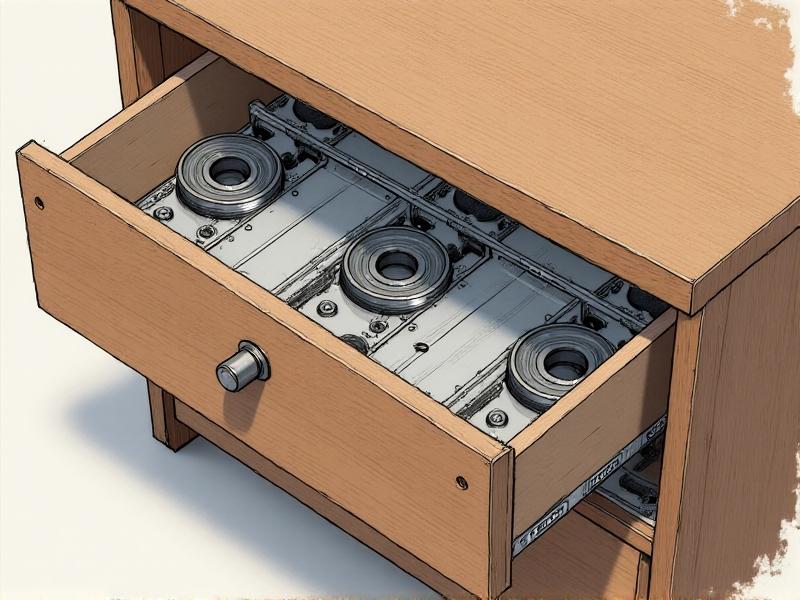

The Silent Workhorses: Understanding Drawer Runner Mechanics

Drawer runners are the unsung heroes of functional furniture, enabling seamless opening and closing while bearing the weight of contents. These systems typically consist of metal or nylon tracks paired with rolling or sliding components. Over time, dust accumulation, misalignment, or wear on contact points can disrupt their smooth operation. Understanding the interplay between materials—such as stainless steel bearings and polymer glides—reveals why proper maintenance matters. Even minor grit or corrosion can amplify friction, transforming a once-effortless glide into a jarring struggle.

Common Culprits: Diagnosing Drawer Runner Breakdowns

Diagnosing issues starts with recognizing symptoms: uneven movement, grinding noises, or drawers that sag when opened. Side-mount runners often fail due to loose screws distorting the track angle, while undermount systems suffer from bent carriage arms. Wood-on-wood traditional drawers may develop swollen areas from humidity changes. Surprisingly, 40% of runner failures stem from improper installation—a problem that manifests months later as cumulative stress takes its toll. Testing empty versus loaded drawer movement helps isolate whether issues stem from mechanical failure or weight distribution.

DIY Rescue Tactics: From Lubrication to Realignment

Many rehabilitation projects require only basic tools and patience. Graphite powder or silicone-based lubricants rejuvenate sticky metal tracks without attracting dust like oil-based alternatives. For wooden runners, rubbing paraffin wax along contact points reduces friction. Realigning drawers demands measuring equal gaps on both sides while adjusting mounting screws in 1/8-turn increments. Temporary shims made from playing cards can compensate for warped frames during adjustments. Always test movements incrementally—forcing a stuck drawer risks permanent damage to joinery or internal components.

When to Upgrade: Modern Runner Technologies

Persistent issues may signal the need for modernization. Soft-close systems use hydraulic dampers to prevent slamming—a worthwhile upgrade for child-safe homes. Full-extension runners provide complete access to deep storage spaces, ideal for pantry units. Commercial-grade epoxy-coated runners withstand 150+ lb loads for garage tool chests. When retrofitting older furniture, consider low-profile adapters that preserve original aesthetics while adding ball-bearing functionality. Material compatibility is crucial; some vintage woods require custom bracketing to handle contemporary metal hardware.

Preventive Care: Extending Runner Lifespan

Proactive maintenance prevents 70% of runner failures. Bi-annual cleaning with a dry bristle brush removes abrasive particulates before they embed in lubricants. Seasonal humidity checks help wood components maintain stable dimensions—a hygrometer guides necessary adjustments. Avoid overloading drawers beyond manufacturer recommendations; redistributing weight preserves balance. Applying felt pads to bottom edges of heavy items minimizes impact forces during closure. For heirloom pieces, create a maintenance log to track adjustments and anticipate wear patterns.

Eco-Conscious Rehabilitation: Repair vs. Replace

Sustainable rehabilitation considers environmental impact at every turn. Repairing existing runners saves 85% of the carbon footprint compared to manufacturing new components. Metal parts can often be refurbished through ultrasonic cleaning rather than replacement. When upgrades are unavoidable, seek Forest Stewardship Council-certified wood replacements or recycled aluminum tracks. Community tool libraries provide access to specialized jigs for precise drilling, reducing DIY waste. Documenting and sharing repair processes online fosters a culture of conservation over consumerism.

Professional Insights: When to Call a Specialist

Complex cases demand professional expertise—like curved antique runners requiring custom laminating or CNC-milled replacements. Specialists bring solutions like laser alignment tools and moisture content meters that prevent trial-and-error damage. Their knowledge of historical construction techniques preserves authenticity in restoration projects. Many offer reconditioning services for premium hardware, salvaging irreplaceable components through electrochemical rust removal and re-tempering processes. Always request material samples and maintenance guidelines post-service to protect your investment.

Future-Proof Design: Innovations in Motion Technology

The frontier of drawer technology integrates smart features without sacrificing reliability. Voice-activated opening systems employ whisper-quiet linear actuators. Self-lubricating polymers infused with nanoparticles promise maintenance-free operation for decades. Experimental magnetic levitation systems eliminate physical contact entirely, though current iterations remain cost-prohibitive. As 3D printing evolves, on-demand replacement parts tailored to exact wear patterns may become standard. These advancements underscore the enduring importance of smooth transitions in our daily interactions with functional spaces.